EMI Well Head Tubing Inspection

Our fleet of EMI Well Head Tubing Inspection trucks and experienced operators are ready to scan and sort your production tubing, so you know what is safe to put back in the well. Operating 20 scanning trucks in the 5 state Rocky Mountain region, we are ready 24 hours a day to meet your scanning inspection needs.

Every individual EMI scanning unit has been inspected and certified by the CSA to be Class 1 Division 1 rated.

Hydro-static testing your tubing back into the well gives you peace of mind, every connection is solid and your tubing isn't compromised.

Do you have a pile of used, dirty, bent pipe with bad threads and unknown structural integrity sitting in your yard? Was your rental string returned in good condition? Do you need a custom part machined to get back in service? We can help. Schedule an appointment for our fleet of trucks to pick up your tubing today.

- Clean Full Length ID / OD

- Full Length Drift

- 4 Function EMI Inspection

- Straighten

- Coupling Removal and Installation

- New Couplings - Full Inventory

- Re-thread Connections

- Manganese Phosphate Coated Connections

- Stationary Hydrotesting up to 10,000 PSI

- Tubing Delivery & Pickup

- Well Head Repair

- Cross Over Subs

- Specialty Connection Repair

- Welding

- Fabrication

Our training, safety and quality programs set us apart from the competition.

- Dedicated Training School

- Horizontal Rig Simulator

- Truck Operator Simulator

- SSE Program with Dedicated Mentor

- Apprenticeship program

- OSHA 10 Hour

- PEC Safeland

- PEC H2S Clear

- First Aid, CPR & AED

- Defensive Driving

- Fork Lift

- In Depth New Hire Safety Orientation Classes

- Trucks GPS Monitored

- Hazard Observation Program

- Behavior Based Safety Program

- Dedicated Quality Assurance Director

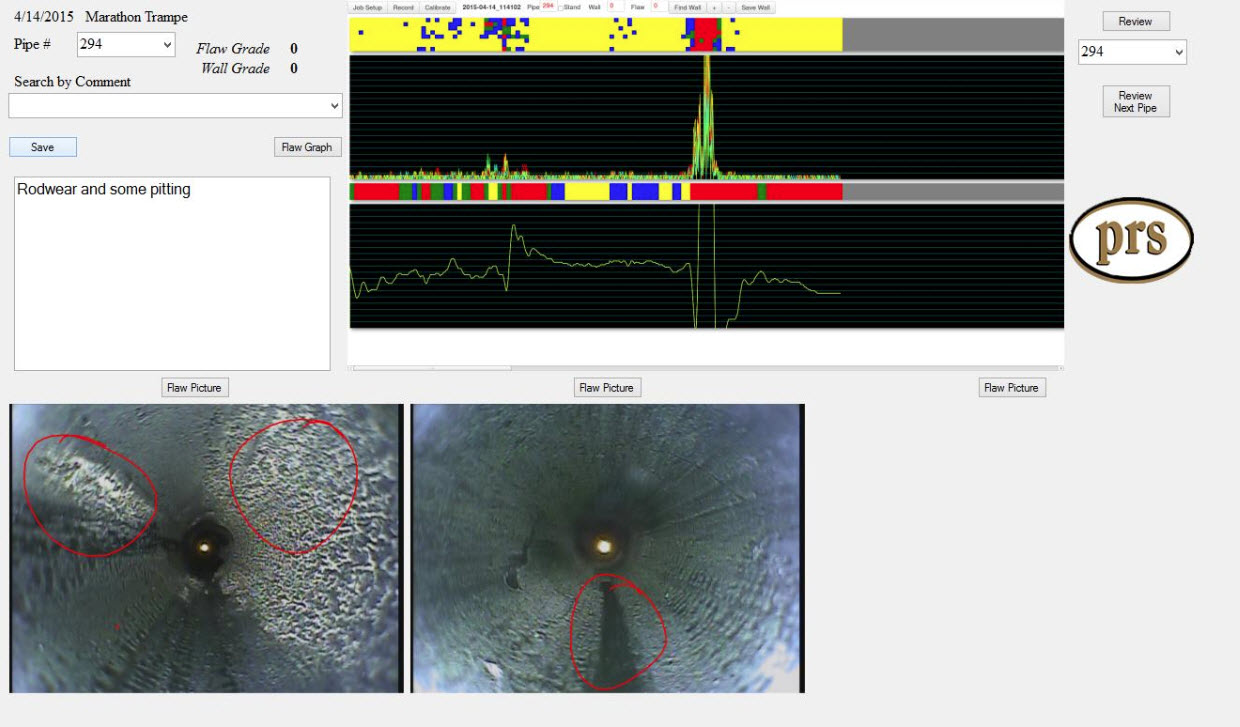

- Cloud based job review by trained QHSE professionals.

- Ability to use real job scan data for training.

- Proprietary data analytic system.

- Data insight reports provided to our customers.

- Field audits by our QHSE professionals.

- Scheduled maintenance program overseen by our QA Director.